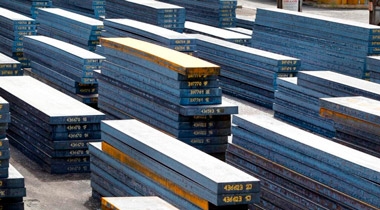

Hot rolled commercial slabs with a thickness of 120 mm to 300 mm are intended for further production of thick sheets and hot-rolled coils from them.

From steel grades:

S235JR, S235J0, S235J2, S275JR, S275J0, S275J2, S355JR, S355J0, S355J2. EN 10025..ASTM A568.

Hot steel sheets are a type of flat rolled metal obtained by cross-cutting hot-rolled coils after they have been rolled in semi-continuous or continuous states. Like rolled products, steel sheets are used in construction, engineering, automotive, consumer goods production.

Application of hot rolled steel sheet

Hot-rolled sheet metal is used in the manufacture of metal structures, profiles, facade elements, door panels and openings, communication protection elements, and consumer goods. The key requirements of this segment for HA sheets are minimum dimensional tolerances, weldability, high strength and toughness, crack resistance. In the construction sector, there is a trend to replace cold-rolled steel with cheaper thin hot-rolled steel. At the same time, high-strength types of rolled products are increasingly being used to reduce the weight of products.

The main standards for technical conditions used in the production of hot-rolled steel are:

- European standards: EN 10025, EN 10028, EN 10111, EN 10149, DIN 17100, EN 10083, EN 10120

- American standards: ASTM A36/A36M, ASTM A1011/A1011M, ASTM A568, API standards and others.

Cold rolled steel sheet is produced:

- By dissolving cold-rolled coils on special cross-cutting or combined cutting units, followed by straightening, packaging and marking of the finished cold sheet.

- By sheet processing of hot-rolled semi-finished products on non-reversible states of cold rolling. In this case, hot-rolled coils are used as the initial billet, which are pre-cut into sheets. The cold-rolled steel sheet is subjected to digestion in batch units, and then, in the cold state, it is deformed in rolling rolls to obtain cold-rolled sheets of smaller thickness.

Various country standards for cold rolled steel specifications, such as EN 10130, EN 10268, EN 10209, ASTM A1008/A1008M, and others. their purpose, the level of mechanical properties, surface quality and other parameters of the cold rolled sheet.

The most commonly used European standards for the production of cold rolled steel are EN 10130, EN 10268 and EN 10209.

The EN 10130 standard applies to low-carbon steel sheets DC01, DC03, DC04, DC05, DC06, DC07 for cold working, uncoated, with a rolled metal width of at least 600 mm and a minimum thickness of 0.35 mm.

Galvanized sheet products are cold-rolled or hot-rolled steel sheets with a zinc coating applied to them, which helps protect the base metal from atmospheric corrosion. Galvanized sheet steel is in demand in those sectors of industry where high requirements are placed on corrosion resistance, durability, strength, appearance, and at the same time, the suitability of products for profiling, stamping, applying various types of additional coatings is important. Key standards in the field of galvanized sheet production are EN 10346 (Europe), ASTM A653/A653M (USA)

Galvanized sheet is widely used in the following fields:

- galvanized sheets are widely used in construction in the manufacture of structural elements of low-rise construction (LSTK), in the sheathing of heating mains and various thermal insulation, in the manufacture of entrance doors, elevators, reinforcing profiles for PVC windows and plastic doors, euro fasteners for drywall;

- in the automotive industry for the front and internal parts of the car body, repair of the front parts of the body of public transport (buses, trams);

- in general engineering and instrumentation for housings of electrical and mechanical equipment, household appliances, elements of metering devices, packaging.